The secret of

Murelle Revolution

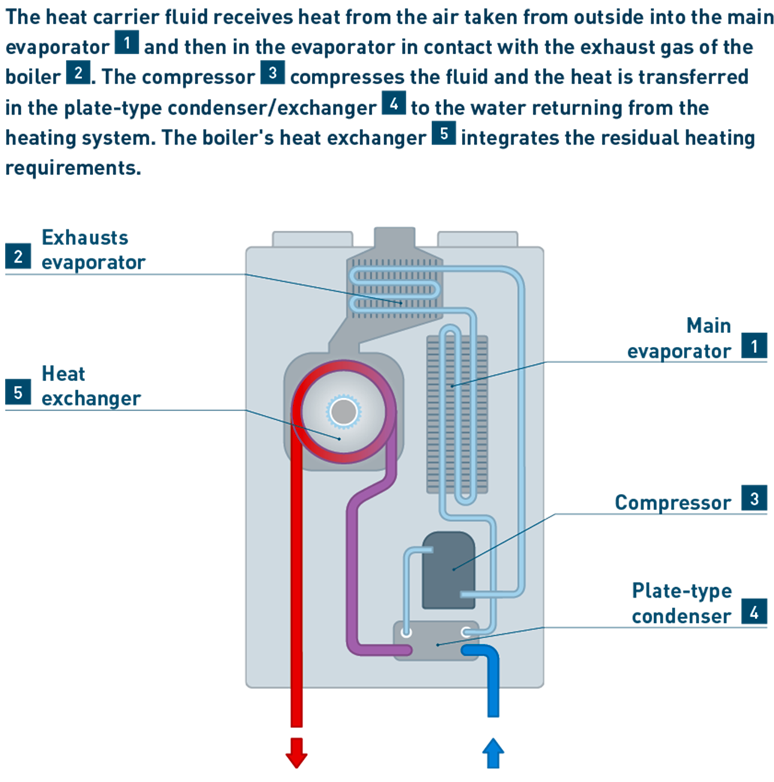

The Murelle Revolution innovation lies in the heat pump circuit that integrates two evaporators: one exchanges with the outside air via the conductors in the upper part of the device and the other is a completely new and patented gas/fluid heat exchanger that permits the recovery of the residual heat of the combustion products.

The gases in a condensing boiler have a relatively high temperature to permit the evaporation of gas in the compressor circuit.

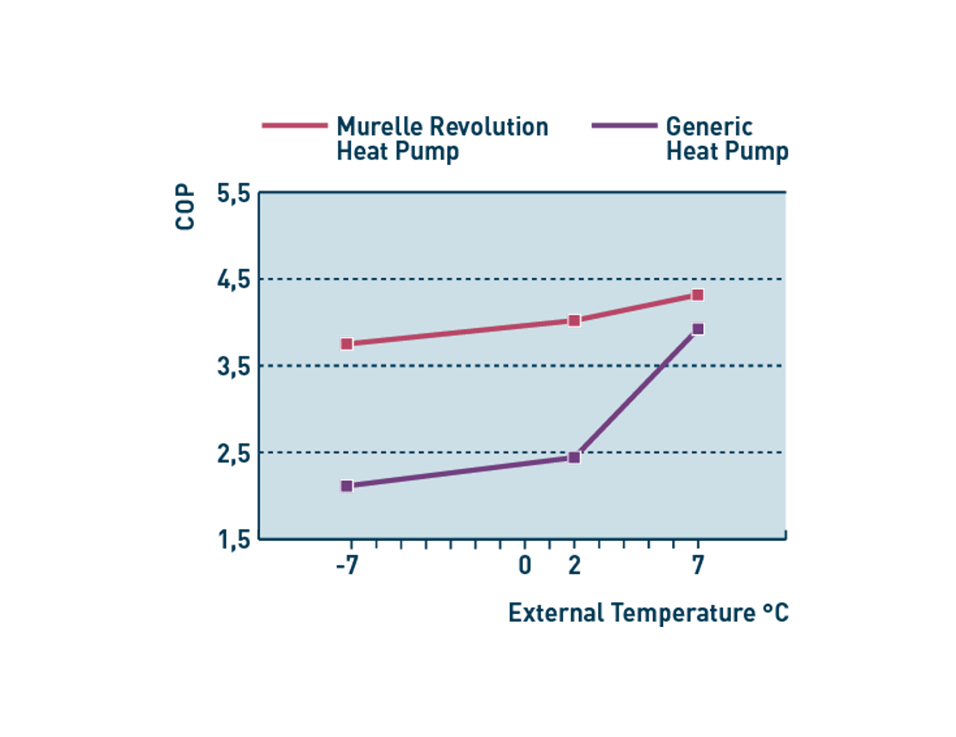

In this way the COP of the heat pump remains relatively constant regardless of the temperature of the outside air. The efficiency of the heat pump/boiler is shown by the fact that the combustion gases exit the device after exchange at around 10°C.

For water heating, the heat pump condenser is connected in series to the heat exchanger of the boiler and pre-heats the return water permitting the boiler to work with a lower temperature difference between delivery and return and modulate the supplied power; in this way gas consumption is reduced as are CO2 emissions into the atmosphere.

Efficiency is so high that combustion exhausts exit at around 10°C